Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

News

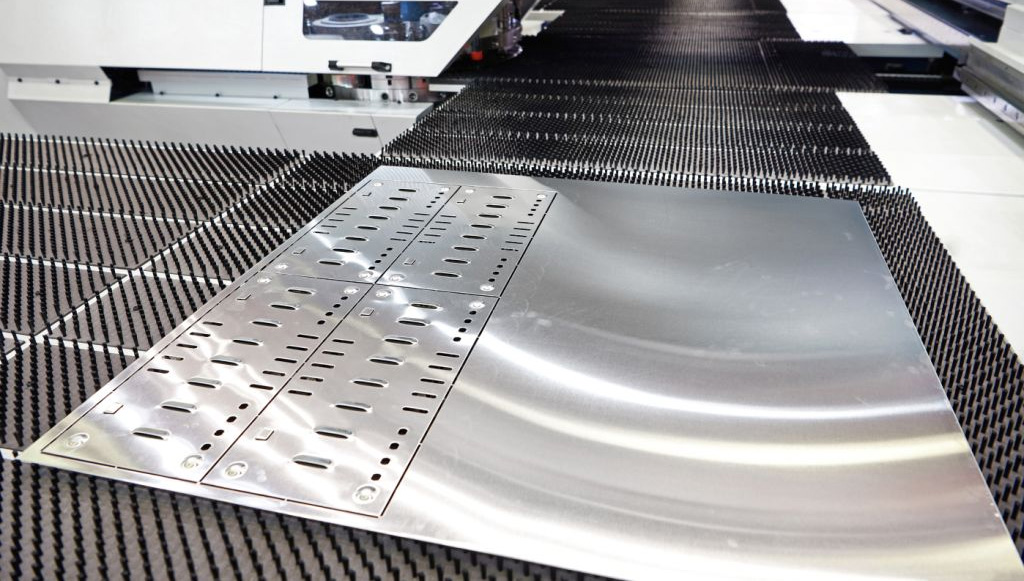

Fiber Laser Cutting Machine Buying Guide: What You Need to Know

Buying a fiber laser cutting machine is a big decision - you'll want to think about the specs, what you actually need it for, and what's out there in the market. These machines aren't cheap - they can cost anywhere from 20k to 200k for industrial-grade systems, so knowing what to look for will help you pick the right one for your metal fabrication work.

The laser source is the most important part. Top brands like IPG Photonics and SPI (which is British but now owned by Trumpf) are known for reliability, while Chinese brands like Raycus offer more budget-friendly options. The power output affects both what the machine can cut and the price. Machines with 1kw - 3kw are great for sheet metal, while 6kw+ models can handle thick plates (up to 25mm). Newer models also have smart power adjustment function, which saves energy (up to 30% more efficient than older ones).

Not all machines cut the same. For sheet metal, look at positioning accuracy and repeatability. Tube-cutting machines cost more because they have extra rotating parts, but good ones come with features like auto chuck adjustment and real-time diameter correction. When shopping around, go for machines with auto-focus cutting heads and collision protection - these features save a lot of downtime. Buy fiber laser cutting machine for Sale - SUDA Laser can be your trusted brand.

European brands like Trumpf and Bystronic still lead in high-end machines, but Chinese brands now make up over 60% of the global market due to lower prices(click to check laser cutting machine price). Just keep in mind that recent US tariffs add around 20% to Chinese imports, so some buyers are looking at local options instead. Besides, more people want hybrid machines that can cut both sheets and tubes, and automation is becoming standard even in mid-range models.

Fiber lasers use 70% less energy than CO2 lasers and have 30% lower maintenance costs because of fewer parts to replace. But you'll still have yearly expenses like protective windows, nozzles, and gas. Some newer machines come with predictive maintenance, which can warn you before something breaks, saving you money on surprise repairs.

Always ask for test cuts on materials you usually work with. A good dealer should provide free samples showing how the machine handles different metals. Pay attention to edge quality on corners and small holes - this tells you how precise the machine is. Lastly, make sure the supplier offers good training and local support—even the best machine won't perform well if your team doesn't know how to use it properly.

Leave a Comment