Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

News

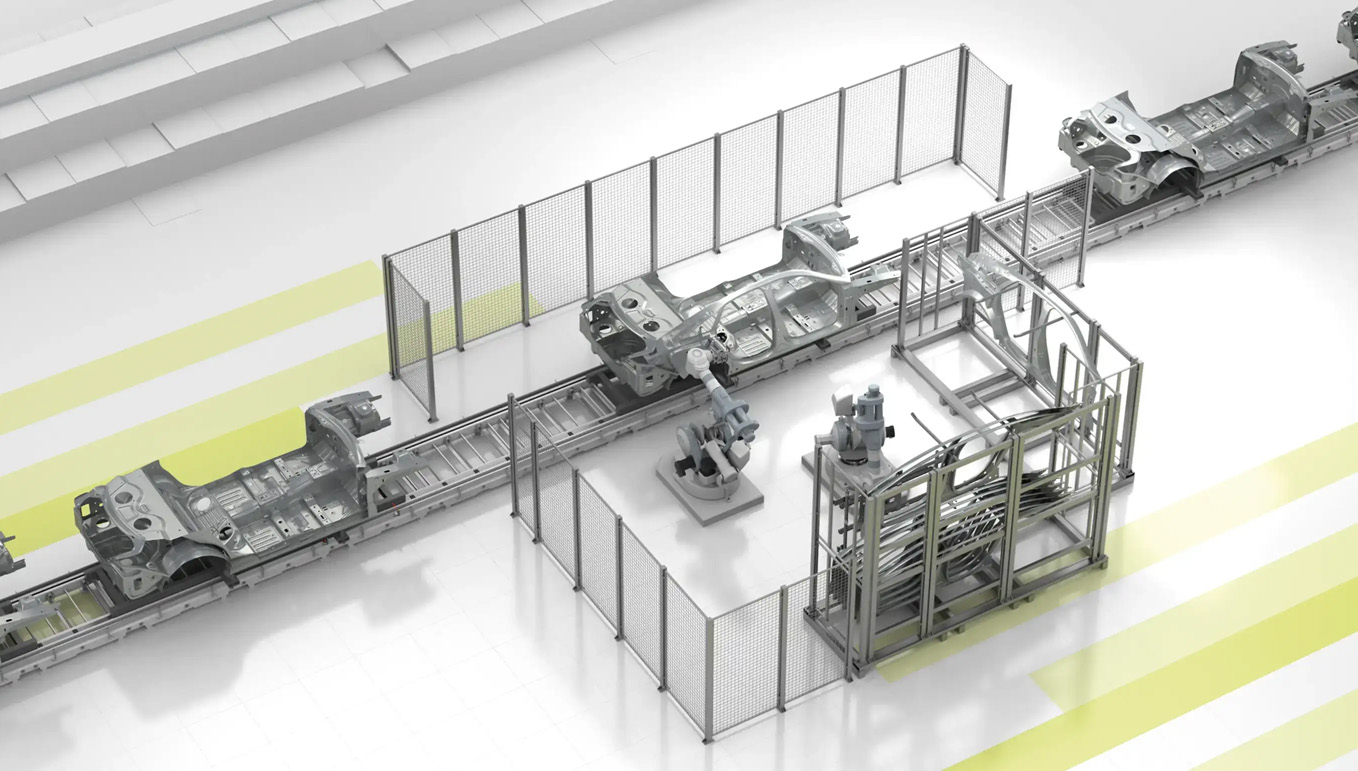

How Laser Cutting is Enabling Innovation in the Automotive Industry

Compared to plasma cutting and traditional sawing machines, fiber laser cutting machine is much more efficienct and energy saving, so that the dominance of CO2 laser cutter in metalworking industry has gradually declined. Having spent a good couple of decades now immersed in the laser cutting machine industry, it's genuinely exciting to witness the profound impact our technology continues to have across various sectors. And nowhere is this more evident, or more dynamic, than in the automotive industry. For years, automotive manufacturing has been synonymous with precision and efficiency, and the latest advancements in laser cutting are proving to be pivotal in pushing those boundaries even further.

One of the most significant shifts I've observed in the last year or two is the relentless march towards lighter, yet stronger, vehicle designs. This isn't just about fuel efficiency anymore; it's crucial for the burgeoning electric vehicle (EV) market, where every kilogram saved translates directly into increased range. Fiber laser cutting machine technology has been instrumental in this evolution. Its ability to precisely cut complex shapes from advanced materials like high-strength steel and aluminum alloys, with minimal heat-affected zones, is a game-changer. We're seeing manufacturers increasingly adopt these techniques for everything from intricate chassis components to lightweight battery housings.

The demand for high-precision laser cutting is also booming rapidly. Modern vehicles are packed with sophisticated electronics and safety systems, requiring components with incredibly tight tolerances. Traditional cutting methods often struggle to meet these demands consistently and require higher cost-effectiveness, meanwhile SUDA Laser offers suitable fiber laser metal cutter. Fiber lasers, on the other hand, offer exceptional accuracy and repeatability, ensuring that critical parts fit together flawlessly. This not only improves the overall quality and safety of vehicles but also streamlines the assembly process, reducing production times and costs.

Furthermore, the trend towards high power laser cutting machine is becoming increasingly pronounced. While lower power lasers have long been the workhorse for thinner materials, the need to process thicker gauge metals efficiently is growing. This is particularly relevant in the production of structural components and heavy-duty vehicle frames. Recent advancements in laser source technology have made high-power fiber lasers more accessible and reliable, allowing for faster cutting speeds and increased throughput without compromising on precision. We're seeing figures suggesting a year-on-year increase of around 15-20% in the adoption of high-power industrial laser cutter solutions within the automotive sector, a clear indicator of their growing importance. If your business involves metal sheet or tube processing, purchasing your own laser cutting machine can significantly reduce operational costs.

At SUDA LASER, we've been at the forefront of these developments, constantly innovating to meet the evolving needs of our automotive partners. Our range of metal sheet laser cutting machine and heavy duty laser cutting machine solutions are designed with these industry trends firmly in mind. We understand the critical need for speed, precision, and reliability in automotive manufacturing, and our machines are engineered to deliver exactly that. For instance, our latest generation of fiber laser cutters incorporates advanced beam delivery systems and intelligent control software, allowing for unprecedented levels of accuracy and efficiency even when processing complex geometries and challenging materials.

The automotive industry is in a period of significant transformation, driven by electrification, autonomous driving, and increasingly stringent environmental regulations. Laser cutting technology is not just keeping pace with this change; it's actively enabling it. 5 axis robotic 3D laser cutting technology is best choice for the high-end aerospace and automotive industries. It's a privilege to be a part of this evolution, and we at SUDA LASER are committed to continuing to provide cutting-edge solutions that empower the automotive industry to reach new heights.

Leave a Comment