Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

News

Industry 4.0 Meets Fiber Lasers: How Smart Technology and High-Power Lasers are Shaping the Future

The fiber laser cutting machine industry is evolving rapidly, driven by technological advancements and increasing demand for high-speed, precision cutting solutions. This technology has become indispensable in industries such as automotive, aerospace, and electronics, where high precision, low operating costs, and reduced material waste are crucial. As a result, fiber laser cutting machines are increasingly being recognized as the future of manufacturing. Leading manufacturers, like SUDA, are leveraging these trends to provide cutting-edge solutions to meet the needs of industries worldwide.

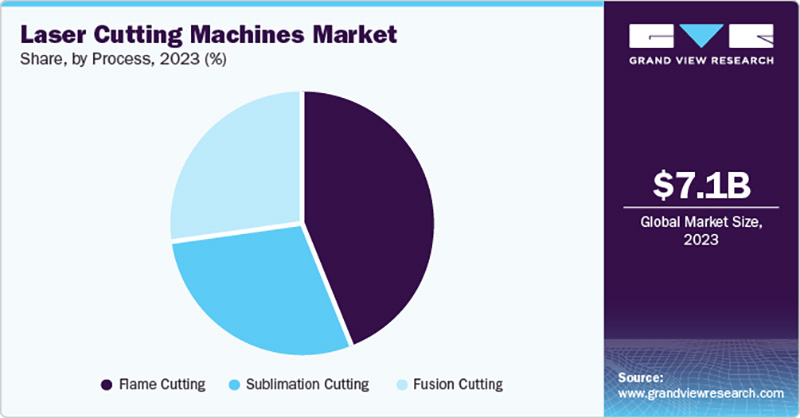

One of the most significant trends in the fiber laser cutting market is the rise of ultra-high power fiber lasers. These lasers, capable of reaching power levels exceeding 20 kW, allow for the efficient cutting of thick materials like stainless steel, aluminum, and copper. According to Laser Focus World, the adoption of high-power fiber lasers is expanding rapidly across industries that require cutting of thicker and harder materials.

We'd love to have you visit the SUDA Laser Cutting Machine factory. We've got 30 years of experience and a huge, top-notch facility, plus we offer great after-sales service. View on Google Map

This trend is not only about raw power but also about improved precision and efficiency. With the ability to reduce heat-affected zones (HAZ) and minimize distortion, high-power fiber lasers allow manufacturers to achieve high-quality cuts even in thicker materials. This is especially important for industries like aerospace, where precision is critical for the structural integrity of components.

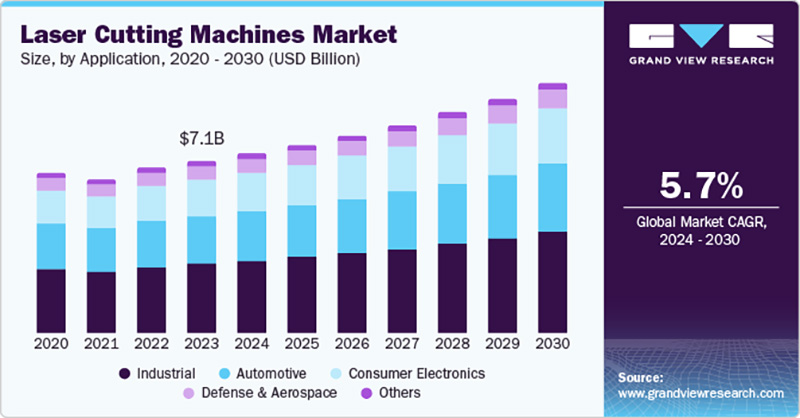

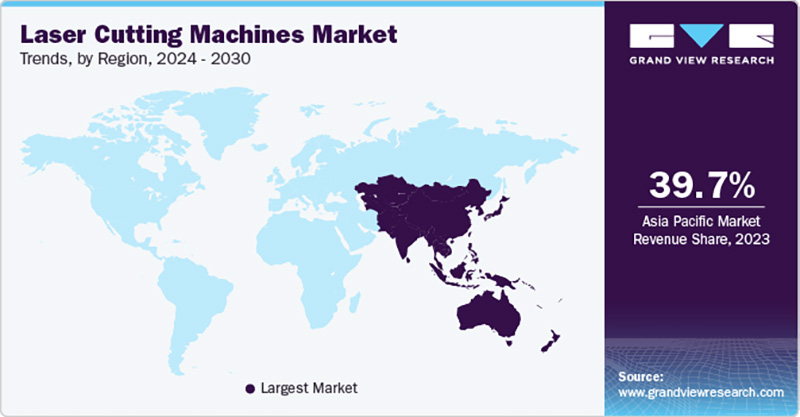

The global fiber laser cutting machine market is projected to grow at a compound annual growth rate (CAGR) of 8.4% from 2023 to 2030, according to recent reports. This growth is driven by the increasing adoption of fiber laser technology in emerging markets, such as Brazil, India, and Turkey, as well as in more established markets like North America and Europe. For instance, the automotive sector in the United States has been one of the key drivers of demand for fiber laser cutting machines. Companies are seeking faster and more accurate cutting solutions to improve production efficiency and reduce operational costs. In regions like Poland and Turkey, demand is also growing in industries such as metalworking and electronics, where fiber laser cutting technology is being used for precision parts manufacturing.

As the market expands, manufacturers are also prioritizing machine reliability and energy efficiency. Fiber laser cutting machines are known to consume significantly less energy compared to traditional methods, making them an attractive choice for manufacturers aiming to reduce their operational costs and environmental impact. SUDA's machines, such as the F3000 Laser Cutting Machine series, are engineered with energy efficiency in mind, helping customers minimize waste and reduce overall energy consumption. Leave us a message if you want to buy laser cutting machines and cnc routers from reliable China manufacturer.

Fiber laser cutting technology is increasingly being applied in non-traditional sectors. For example, in the renewable energy industry, fiber lasers are used to cut parts for solar panels and wind turbines. As the demand for clean energy continues to grow, the need for efficient, high-precision cutting solutions is also increasing. Sustainability is a key focus for many manufacturers, and fiber laser cutting technology offers several environmental benefits. Unlike traditional cutting methods, fiber lasers produce fewer waste and require less energy, which helps companies reduce their carbon footprint. In fact, Laser Focus World reports that fiber laser cutting machines are up to 40% more energy-efficient than traditional cutting technologies.

In addition to energy efficiency, fiber lasers contribute to higher material utilization. This is particularly important in industries where raw materials are expensive, such as aerospace and automotive. The precision of fiber lasers allows manufacturers to cut complex shapes with minimal material wastage, making them an attractive option for cost-conscious businesses.

Looking ahead, automation and smart manufacturing will play a major role in shaping the future of fiber laser cutting. With the integration of AI and IoT (Internet of Things), manufacturers are increasingly able to automate their production lines, leading to greater efficiency and reduced human error. Automated systems can also monitor machine performance in real-time, predicting maintenance needs and optimizing cutting parameters for each job. SUDA is already integrating these smart technologies into our products. Our advanced systems allow for real-time monitoring and optimization, helping manufacturers improve productivity while reducing downtime.

The fiber laser cutting machine industry is on an exciting growth trajectory, driven by advancements in laser technology, increasing market demand, and a focus on sustainability. As the technology continues to evolve, manufacturers like SUDA Laser are at the forefront of offering high-performance, durable machines that meet the diverse needs of industries worldwide. With applications spanning from automotive to renewable energy, fiber laser cutting is poised to remain a cornerstone of modern manufacturing, offering unparalleled precision, efficiency, and cost-effectiveness for years to come.

We are pleased to invite you to visit us at the ISA International Sign Expo 2025, Booth no.3660, taking place from April 23 to April 25, 2025, at the Mandalay Bay Convention Center in Las Vegas, Nevada. During the event, you will have the opportunity to explore our high-precision fiber laser cutting machines and CNC engraving and milling machines. We look forward to connecting with you at the expo.

Leave a Comment