Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

News

Strategy for Choosing the Right Fiber Laser Cutting Equipment

Choosing the right fiber laser cutting machine is crucial for businesses in metal fabrication, automotive, aerospace, and electronics industries. With so many options available, it's important to consider factors like power, precision, speed, and cost. SUDA Laser will guide you through the key points to help you make the best decision. What's more, if you want to buy laser cutting machine, cast a glance at SUDA Laser, I'm sure you will find ideal equipment.

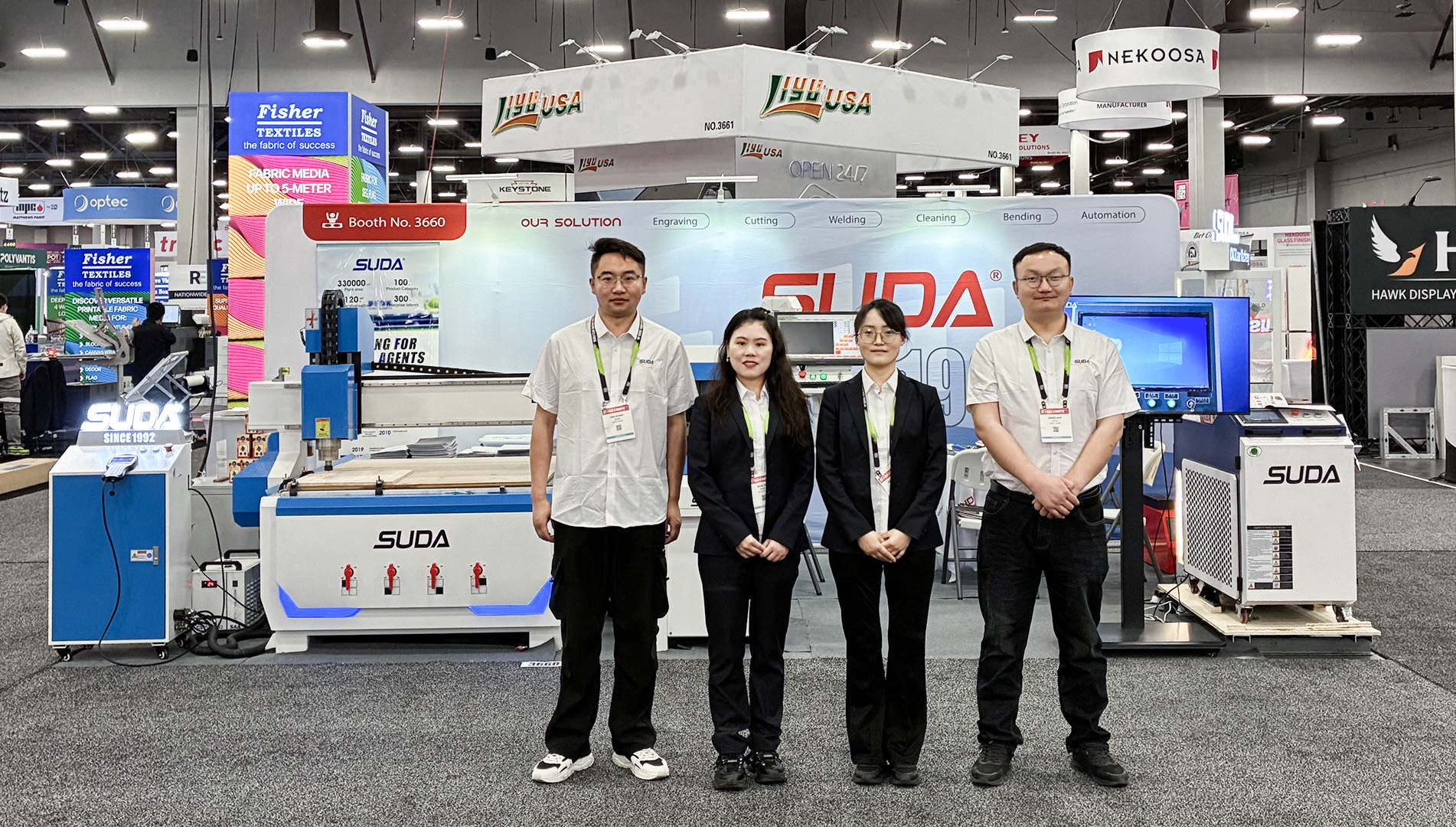

SUDA Laser at ISA Expo 2025

First, determine the power you need. Machines like the 1500w laser cutting machine are ideal for thin metal sheets, while higher-power models (2000W-4000W) handle thicker materials like stainless steel and aluminum. For example, the 3015 laser cutting machine is a popular choice for medium-scale production due to its universal table size - most of materials won't be larger than 1500mm × 3000mm. If your work involves stainless laser cutting machine applications, look for models with nitrogen gas support to ensure clean cuts without oxidation.

Next, consider speed and precision. A high speed laser cutting machine can significantly boost productivity, especially in industries requiring mass production. Some newer models, like the F6000 Laser Cutting Machine, offer cutting speeds up to 180m/min while maintaining accuracy within ±0.05mm. If your work involves intricate designs, precision is even more critical.

Another important factor is the machine's design. An enclosed fiber laser cutting machine provides better safety and reduces noise and dust, making it suitable for workshops with strict environmental controls. Fully enclosed models, for example our FV Series Laser Cutting Machine, also improve stability, especially in high-speed operations. Additionally, machines with dual-station work modes can further enhance efficiency by allowing continuous loading and unloading. But the price can be very high, when comparing with normal single table laser cutting machines. But one thing you may overlook - products in higher-end series generally have better build quality.

China has become a major player in the fiber laser market, with many manufacturers offering competitive prices. If you're considering a fiber laser cutting machine manufacturer in China, research brands like SUDA Laser, which provide reliable machines with advanced features. However, don't just focus on price - look for after-sales support, warranty, and software compatibility. Some machines come with nesting software to optimize material usage, which can save costs in the long run. One more thing to be considered - a brand's hisotyr matters because without long-term operation, you can't verify the reliability of its after-sale service.

Finally, think about possible future needs. The industry is moving toward automation and smart manufacturing, so choosing a machine that supports upgrades and long history brand is smart choice. Some companies like SUDA Laser are already adopting hybrid machines that combine laser cutting with coil-fed function or bending tools.

Leave a Comment