Union Intelligent CNC Industrial Park A&B, Hefei, China 231131

News

104% Tariff Shock: How the Laser Cutting Industry Will Adapt in 2025

On April 9, 2025, the United States imposed a staggering 104% tariff on goods imported from China, marking a dramatic escalation in global trade tensions. This remarkable increase followed a series of prior tariff hikes, starting at just 10% in early February 2025, then rising to 20% in March, and reaching 54% on April 5th. This rapid escalation was in response to earlier retaliatory tariffs from China, signaling a potentially fundamental shift in trade relations between the world's two largest economies. For numerous industries, including the laser cutting sector, this unprecedented tariff barrier presents significant challenges, forcing businesses to re-evaluate their operations and strategies. From manufacturers utilizing fiber laser cutter and co2 laser cutter technologies to the companies producing these very machines, the impact will be felt across the board.

These tariffs are expected to have far-reaching consequences for broader manufacturing in both the U.S. and China, potentially leading to increased prices, supply chain disruptions, and shifts in sourcing strategies. The high tariffs inherently increase the cost of imported goods, which could compel U.S. businesses to raise prices for consumers, potentially dampening demand and hindering economic growth. Simultaneously, China's export-reliant economy is projected to face significant downward pressure, with one analysis by Goldman Sachs even predicting these tariffs could reduce China's 2025 GDP growth by as much as 2.4%. Specifically within the metal fabrication industry, including businesses utilizing cnc fiber laser cutting and laser cutting for steel, will be directly affected by tariffs on steel and aluminum. Notably, the U.S. had already imposed a 25% tariff on all imported steel and aluminum, which also applies to derivative products like fasteners and hardware. The table below highlights the rapid escalation of U.S. tariffs on China in 2025:

Early February 2025:10%

Early March 2025:20%

April 5, 2025:54% (IEEPA Rate)

April 9, 2025:104% (IEEPA Rate + Additional 50%)

For the laser cutting industry, this translates to a significant increase in the cost of raw materials, coupled with a potential decrease in demand from industries that rely on laser-cut components, such as the automotive and construction sectors. Faced with these challenges, businesses will need to proactively explore adaptation strategies to ensure survival and continued growth.

SUDA Laser is not afraid of high US tariffs because we firmly believe in the excellent quality of our products. Our 33 years of production experience and comprehensive after-sales service are our confidence. Our American customers still trust our products and believe that in the near future, Trump will realize the serious harm of the trade war to the economy and people's livelihoods.

To navigate the impact of these high tariffs, businesses in both the U.S. and China may employ various strategies, such as seeking alternative suppliers, investing in domestic production, or exploring new markets. For American corporations, key strategies include a thorough analysis of supply chains, implementing strategic price adjustments, actively renegotiating supplier agreements, exploring product innovation opportunities, and prioritizing clear communication . Supply chain diversification, including nearshoring or reshoring and optimizing the supplier mix, is crucial to reduce reliance on single sources or countries . Within these adjustments, advanced technologies like tube fiber laser cutting machine and laser metal cutting machine may play a pivotal role by increasing efficiency and reducing production costs to offset some of the tariff-related cost increases . The high tariffs may incentivize businesses in the laser cutting industry to increase investments in automation and advanced technologies to improve efficiency and reduce reliance on imported materials or components. Furthermore, as importing laser cutting components or entire laser cutting machines becomes prohibitively expensive from China, the tariffs may lead to increased demand for domestically produced laser cutting services and machines.

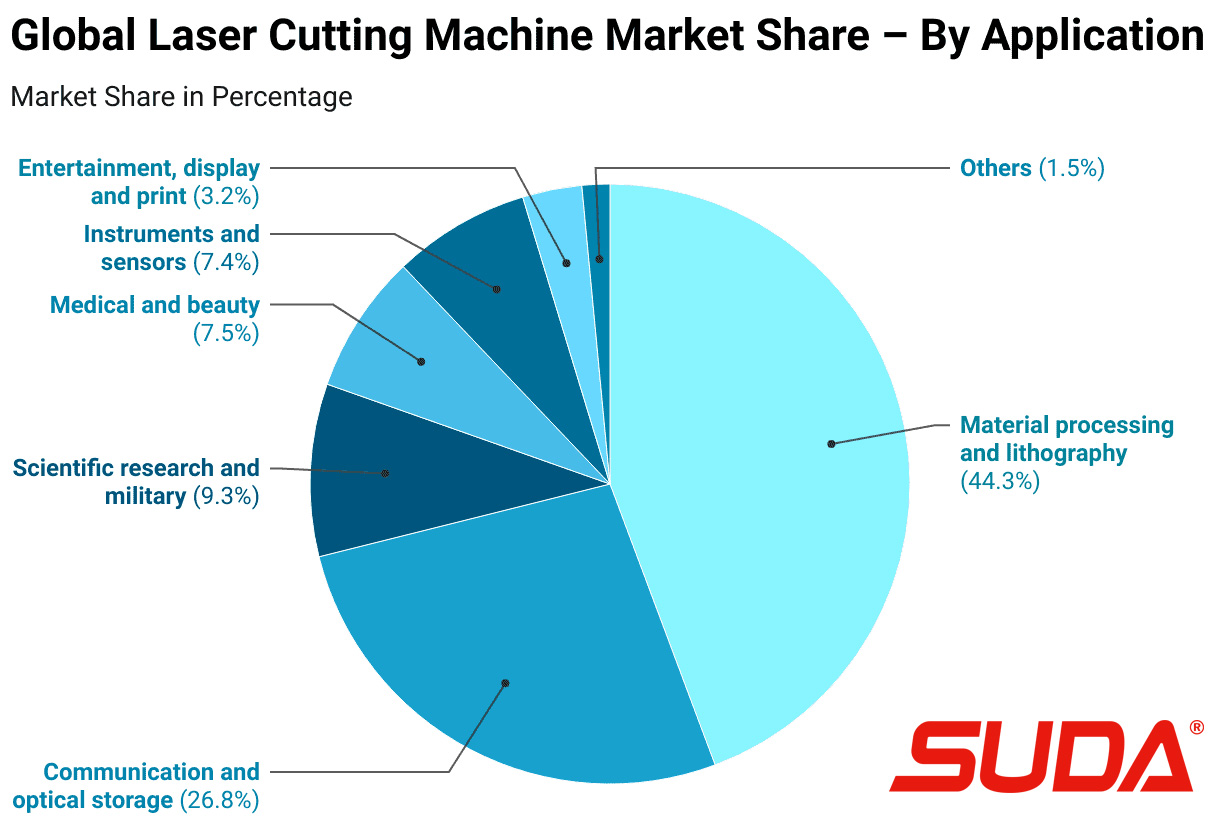

The global laser cutting machine market was valued at USD 6.31 billion in 2024 and is projected for significant growth in the coming years . CNC fiber laser technology, known for its efficiency and suitability for metal cutting, is a key driver of this growth . As laser cutting machine manufacturer, particularly those based in the America., may see increased demand for their products as the cost of imports from China rises dramatically . However, U.S. manufacturers may also face higher costs for imported components if those are also subject to tariffs. Some reports suggest that certain metalworking machinery from China might be considered for tariff exclusions to avoid penalizing U.S. manufacturers. The 104% tariff is likely to cause a significant shift in the laser cutting machine market landscape. Chinese manufacturers may become less competitive in the U.S. market, while manufacturers from other regions, such as Europe, Japan, and South Korea, may acquire more benefits in opposite. And the American manufacturers may also see a surge in demand . However, businesses will need to closely monitor changes in tariff policies, as potential exclusions for certain manufacturing equipment or their critical components could significantly alter the competitive dynamics and provide relief for both manufacturers and end-users.

In conclusion, the imposition of a 104% tariff by the U.S. on goods from China presents unprecedented challenges for the laser cutting industry. While these tariffs aim to revitalize domestic manufacturing, they also bring significant cost increases and potential supply chain disruptions. To survive and thrive in this new trade environment, businesses in the laser cutting sector will need to be proactive, diversifying their supply chains, investing in advanced technologies to enhance efficiency, and closely monitoring evolving trade policies. The market dynamics are likely to shift significantly, creating new opportunities for those who can adapt quickly and innovate to overcome these challenges.

There is no winner in a trade war, and any attempt to boycott other countries' normal sales of products with high tariffs will result in self inflicted consequences. Improving the competitiveness of domestic enterprises' products is what governments should do.

Leave a Comment